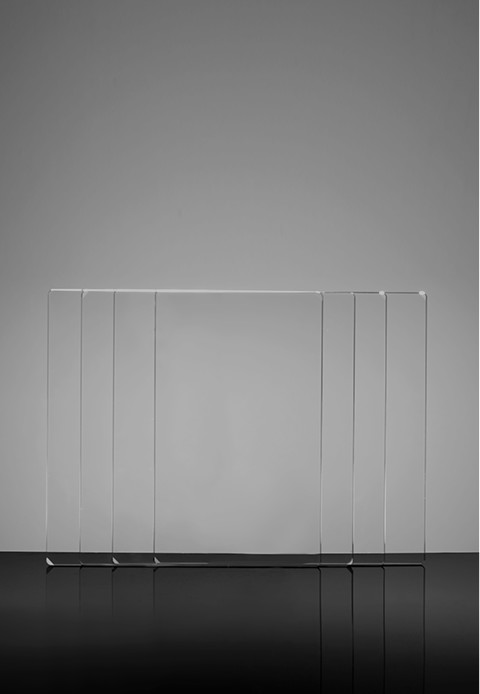

QUARTZ MATERIAL

Aura Optics Group Co., Ltd. was founded on June 27, 2007, with a registered capital of 186.07 million yuan. Shenguang Optics originated in 2002, focusing on the research and production of high-quality synthetic fused quartz glass for more than 20 years. The company specializes in the development of synthetic ultraviolet fused quartz glass (Class I, JGS1, ZS) technology.

In 2005, we broke through the bottleneck of large-scale fused quartz glass production technology and produced the first domestically produced Φ 230 × 1570mm fused quartz glass wool weight, pioneering the production of ultraviolet fused quartz glass using vertical deposition technology in China. As a pioneer in vertical sedimentation technology in China, Shenguang has successfully broken the long-standing technological backwardness of the industry with solid technical strength, and promoted the technological upgrading and leapfrog development of the entire industry chain.

The company is committed to independent innovation, focusing on tackling key core technologies and possessing multiple national patents. The company has undertaken more than 20 national, provincial, and municipal scientific research projects, with key technical indicators leading domestically and reaching international advanced levels. The company's products are widely used in aerospace, precision optics, photolithography technology, semiconductors and other application fields. It is the main supplier of high-end synthetic fused quartz glass in China, representing the highest level in the domestic synthetic fused quartz field.

In recent years, the company has made significant progress and landmark achievements in the development of TFT and chip photomask substrates. It has successfully developed multiple semiconductor photomask products, and all technical indicators have met the standards of users, opening a new journey towards the international semiconductor industry.

COMMITTED TO BECOMING A LEADING GLOBAL PROVIDER OF INTEGRATED SOLUTIONS FOR OPTICAL PRODUCTS.

BUSINESS LAYOUT

IUR COOPERATION

Shenguang Optics has a first-class research and development center and production base, and has carried out in-depth cooperation with many domestic universities and colleges to carry out project research and development and subject research. It has established the "Sichuan Shenguang - Wuhan Polytechnic Optical New Material Technology Research Center" with Wuhan University of Technology and a joint laboratory with Southwest University of Science and Technology. In the industry-university-research cooperation with institutes and universities, Sichuan Shinguang has obtained cutting-edge technical theories and experimental results. In the continuous operation and development, Sichuan Shinguang has accumulated advanced technical resources in the upstream and downstream of the supply chain. In the continuous R&D and innovation, Sichuan Shinguang has gradually realized the key technologies to overcome difficulties.

INDUSTRIAL CHAIN COORDINATION

The fused quartz glass produced by Shenguang Optical Group is used to replace the import, which is one of the key components in the construction project of the National Ignition Special - inertial Confinement nuclear fusion project of the Chinese Academy of Sciences. The second is for a variety of precision optical system lens, the company has undertaken the 02 special photolithography machine lens research and development tasks. Third, it is used in the semiconductor industry. The mask plate is a high-precision plate engraved with microcircuits, which is made of quartz plate or glass plate with a layer of chromium on the flat surface. The residual chromium part after etching is the designed micrograph, which is a high-precision tool for graphic transfer in the manufacturing process of LCD and semiconductor, and plays a core role in determining the accuracy of downstream products. At present, it is mainly dependent on imports, which will be greatly alleviated by the completion of the new production capacity of 768 tons of Shenguang Optics, the largest in the world. At the same time, the company actively responds to the national strategy of military-civilian integration, continues to overcome difficulties to promote technology transformation, and strives to open up high-end civilian markets such as large-size photomask substrates and domestic lithography machine materials application. - Optical New Material Technology Research Center of Wuhan Institute of Technology ", which has set up a joint laboratory with Southwest University of Science and Technology. In the industry-university-research cooperation with institutes and universities, Sichuan Shinguang has obtained cutting-edge technical theories and experimental results. In the continuous operation and development, Sichuan Shinguang has accumulated advanced technical resources in the upstream and downstream of the supply chain. In the continuous R&D and innovation, Sichuan Shinguang has gradually realized the key technologies to overcome difficulties.

MAIN ACHIEVEMENT

Through years of continuous practice, exploration and summary, Shenguang Optics has made the following achievements with its technological and R&D advantages

It created the first domestic vertical deposition process to produce UV fused quartz glass, changed the situation of the industry technology for a long time behind, and effectively promoted the upgrading and rapid development of the industry technology

The key index of leading products, optical non-uniformity of large diameter fused quartz glass, has achieved a breakthrough of 8×10-7. The performance indicators of the products are at the leading level in China, and the technical maturity has been significantly improved. It is the only unit in China that has reached this quality level, filling the gap in China.

In 2020, he participated in the formulation of the national standard of "High Permeability opaque quartz Glass", leading the industry innovation with technology and leading the industry.